Seal Test / Sealing Test distribution|seal testing for food packaging : commercial The integrity of seals on packaging for new product introductions and alternate distribution, such as via e-commerce, also needs to be assessed. Maintaining the reliability of package seals is . Salsa Bingo. O Salsa Bingo é um dos jogos de loteria popula.

{plog:ftitle_list}

Family Strokes,FamilyStrokes,free videos, latest updates an.

Testing the integrity of package seals helps ensure that food packaging provides required product protection. Sustainable packaging alternatives, lower cost packaging, and variations in production line sealing parameters are frequently assessed with seal integrity tests.The integrity of seals on packaging for new product introductions and alternate .November 10, 2021. 3 Min Read. Enhanced package seal integrity is once again top-of-mind due to recent supply and demand challenges that include these .

Claire Sand | Nov 10, 2021. Enhanced package seal integrity is once again top-of-mind due to recent supply and demand challenges that include these six reasons: Obtaining consistent .The integrity of seals on packaging for new product introductions and alternate distribution, such as via e-commerce, also needs to be assessed. Maintaining the reliability of package seals is .Validation data on preformed sterile barrier systems. Responsibilities – Medical Device Manufacture. All seals on Form Fill Seal (FFS) Final seal on purchased pouches. Final . To achieve the test purpose, a dynamic sealing test device for shield tail grease is independently developed. The sealing cylinder of the test device is made of black iron and could withstand a maximum pressure of 5.0 MPa, as shown in Fig. 8. The height and outer and inner diameters of the sealing cylinder are 500 mm, 180 mm, and 150 mm .

Jia et al. Journal of Engineering and Applied Science Page 5 of 12 guarantee a high-pressure water seal state; Step 3: permit the ber tail to move in both X and Y directions to replicate the rotary and impact movement of the rock drill’s washing mechanism. Simulation model verication We used experimental data from pertinent literature and set the same parameters in theThe test duration for a potable water supply and distribution piping air test is _. 12 - 24hr A(n) _ leak detector is commonly used to locate small leaks in the potable water supply and distribution piping system. Fig. 12 shows the plot of the cell pressure vs. time of the sealing test. We can understand the LCM sealing behavior by analyzing the curve. The experimental process is divided into three periods, and the curve is divided into three parts: A, B and C regions. The A region is the sealing process by drilling fluid containing LCMs. The easiest to do is hot water seal. Use distilled or demineralised water with a conductivity below 150 microsiemens and a pH of about 6 (5.5-6.5 is not uncommon). . The sealing test is also described by BS EN 12373-6. I don't know if it is exactly the same as the ASTM, I haven't carried out any gap analysis to find out.

Summary Chart: Seven Seal Testing Methods for Flexible Packaging. This summary chart will help you compare all seven seal tests for flexible packaging on your flow wrappers and vertical FFS baggers. If you’d like help defining your sealing objectives and evaluating seal testing methods, contact Greener Corporation. We provide package quality .• Distribution Cycle: the sequential listing of the test schedules employed to simulate the hazard elements expected to occur for a specific routing from production to composition (most fall into DC13 encompassing both air and truck. • Assurance level: the level of intensity based on the probability of occurring in a typical distribution cycle

Package Distribution Testing; ASTM Seal Integrity Testing; Package Development. . a program in which optimal sealing parameters are determined through correlation with low leakage rates. In such programs, there are typically a range of sample sets assembled at capping parameters from very low (aluminum crimp seal barely applied) to very high . Increasing demands for environmental accountability and energy efficiency in industrial practice necessitates significant modification(s) of existing technologies and development of new ones to meet the stringent sustainability demands of the future. Generally, development of required new technologies and appropriate modifications of existing ones . Dye penetration test: An operator applies a dye to one side of the seal area and then examines the other side of the seal to assess if the dye transferred through the seal. Detectable leaks are six orders of magnitude larger than most permeants such as oxygen, carbon dioxide, nitrogen, so this method is not useful to detect small leaks relevant to modified .

sealing cycle but prior to the temperature of the seal reaching ambient. Refer to Test Methods F1921. 3.1.6 seal initiation temperature, n—on a heat seal curve, the sealing temperature/dwell pressure at which heat seal strength first begins to trend upward from zero heat seal strength. 3.1.7 sealing interface, n—the interface of the two webpackage inflation seal strength test. In the Creep Test, a whole package is inflated to a constant pressure, which is then held for a specified time, resulting in a pass/fail result (see Figure 5). Early users of the method for peelable seals used the test as an analogy for the pressure difference on the seals seen in the ETOResidual Seal Force (RSF) • RSF is the Stress A Compressed Elastomeric Closure Flange Continues to Exert on A Vial Land Sealing Surface after Application of an Aluminum Seal (Crimping). • USP <1207.3> Seal Quality Test • Quantifying the RSF is a Test Method for the Indirect Estimation of Elastomeric Closure Compression.

For each test, different evolution of radial swelling pressure was observed, suggesting a heterogeneous structural distribution of bentonite/sand mixture within the blocks. View Show abstract

Seal tests ISO11607-2 (Validation requirements for forming, sealing and assembly processes), requires Operational Qualification (OQ) of packaging devices to be carried out and documented. The OQ is requiring providing proof of: Intact seal for a specific seal width No channels or open seals No punctures or tears in seals No material delaminating or separation The OQ needs to The paper herein presented deals with piston seals accelerated life tests performed by means of a suitable test rig; the sealing capability of the seals is evaluated versus the travelled distance .

The sealing performance of lip seal can be expressed through the contact pressure of seal area in static state and the reverse pump rate in dynamic condition. Admittedly, the friction torque can reflect the working life. In order to evaluate the sealing performance of lip seal, bench test, finite element simulation and numerical simulation are .

seal, a part of the seal holder, and the flow ar eas upstream and downstream of the test seal. The test seal is modelled as a porous medium, assuming that there is no thermal equilib- rium . Experimental investigation has been done to evaluate the leakage performance of labyrinth seal for oil sealing on high-speed sealing test rig at different working and geometric parameters.CS Analytical team can perform a variety of ASTM test methods for detecting leaks and seal integrity regardless of package type or configuration. . Package Distribution Testing; ASTM Seal Integrity Testing . provides a wide variety of approved and validated test methods that address sealing issues for package systems and the CS Analytical .

влагомер бесконтактный

Residual Seal Force (RSF) • RSF is the Stress A Compressed Elastomeric Closure Flange Continues to Exert on A Vial Land Sealing Surface after Application of an Aluminum Seal (Crimping). • USP <1207.3> Seal Quality Test • Quantifying the RSF is a Test Method for the Indirect Estimation of Elastomeric Closure Compression.Hänchen's internal test cycle for a sealing system consisting of a rod and seal combination generally covers 300 km of use in 24-hour operation. Extensive tests of recent years have proven the effectiveness of bronze-filled PTFE seals as the primary seal in combination with a secondary seal and a wiper ring.Twist ’N Seal® Pipe Sealing Plug Product Description and Features. Securely block off a variety of pipes from the inside with the Test-Tite Twist ‘N Seal Pipe Seal Kit. Quick and easy to use, this pipe seal kit allows you to install a temporary sealing plug inside DWV (drain, waste, and vent) pipe, stopping the water flow while you solder .

As referenced under the ISO 11607 Guidelines, there are number of test options and methods that may be implemented to evaluate seal effectiveness: ASTM F88 Seal Strength; ASTM F1140 Burst Test (Unrestrained) ASTM F1886 Determining Integrity of Seals by Visual Inspection; ASTM F2054 Burst Test (Restrained) Moreover, being not often viable to test sealing systems directly in their actual location and environment, many test rigs for sealing system characterization have been designed in the last years . Enhanced package seal integrity is once again top-of-mind due to recent supply and demand challenges that include these six reasons: 1. Obtaining consistent seal layers; 2. The gas seal performance test of metal rubber seals is conducted and the relationship between gas leakage and temperature and pressure is obtained under different test temperatures and gas pressures.

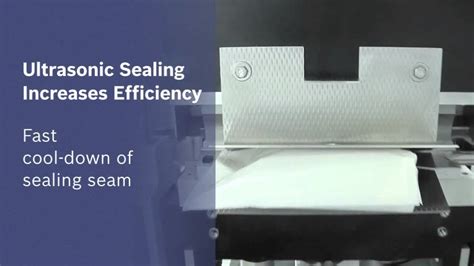

ultrasonic seal testing

seal testing for food packaging

WEB16 de jan. de 2024 · Clube Melancia - Compra Coletiva. clubemelancia. 10 subscribers. Subscribed. 7. Share. 16K views 13 years ago. Entenda como funciona o site de compra coletiva de Presidente Prudente..

Seal Test / Sealing Test distribution|seal testing for food packaging